In the ever-evolving landscape of logistics and supply chain management, the quest for optimizing warehouse efficiency has become paramount. Among the myriad strategies, warehouse slotting emerges as a critical practice, combining both art and science to enhance operations and maximize storage capabilities.

The Foundation of Warehouse Efficiency

At the heart of a well-organized warehouse lies the strategic arrangement of inventory, and that’s precisely where warehouse slotting plays a pivotal role. It involves placing products in specific locations based on various factors, such as size, demand, and picking frequency. This meticulous approach transforms the warehouse into a dynamic space, where every item has its designated spot, contributing to a seamless workflow.

The Art of Warehouse Slotting

1. Understanding Product Characteristics

One of the artistic elements of warehouse slotting involves understanding the unique characteristics of each product. Size, weight, fragility—these factors influence where an item should be placed for optimal storage and retrieval. Delicate items might need to be stored away from heavy machinery, while fast-moving goods should be easily accessible for quick picking.

2. Seasonal Considerations

Just as an artist adapts their palette to the seasons, warehouse slotting adjusts to changing consumer trends. Seasonal items should be strategically placed for efficient restocking during peak times. Winter coats in summer? Keep them in the back. Pool supplies in winter? Move them to a more accessible area.

3. Visual Merchandising Principles

In the retail world, visual merchandising is an art form that influences customer behavior. Similarly, warehouse slotting can benefit from these principles. Grouping related items together and creating visually distinct zones can accelerate the picking process, minimizing errors and enhancing overall efficiency.

4. Intuitive Layout Design

An intuitive layout design is another facet of the art of slotting. Placing frequently paired items in close proximity and ensuring that high-demand products are easily accessible contributes to the intuitive flow of the warehouse.

The Science Behind Warehouse Slotting

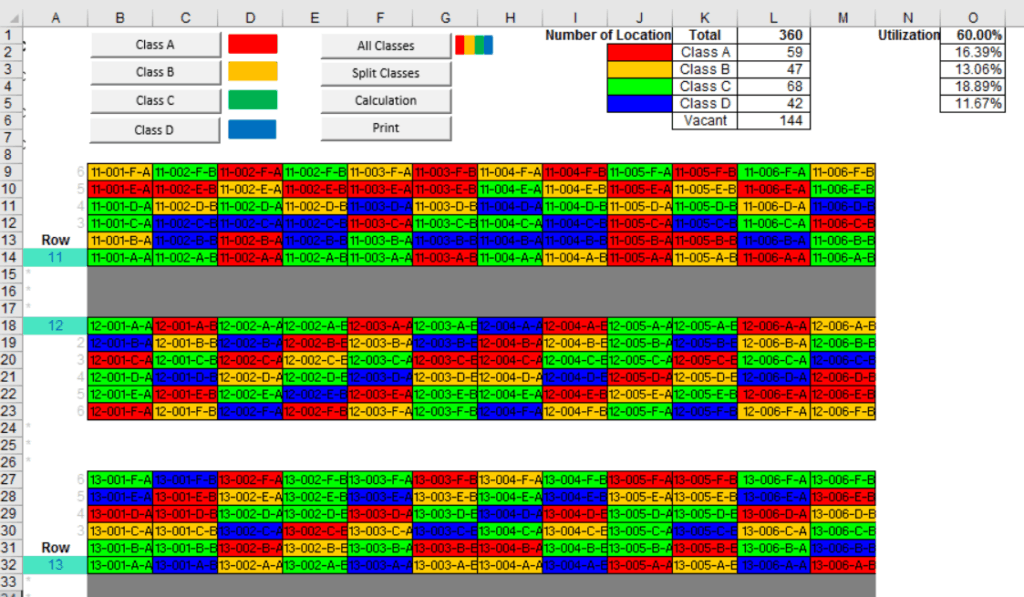

1. ABC Analysis

In the scientific realm of warehouse management, the ABC analysis categorizes items into three groups: A, B, and C, based on their importance. A items are high-value, B items are moderate, and C items are low. Placement of inventory ensures that A items are conveniently located for quick access, optimizing the overall picking process.

2. Picking Algorithms

Sophisticated algorithms form the backbone of warehouse slotting science. These algorithms take into account historical data, order frequency, and other variables to determine the optimal location for each item. As technology advances, machine learning is increasingly applied, refining these algorithms for even more precise slotting.

3. Dynamic Slotting Adjustments

Unlike traditional static slotting, the science of warehouse slotting embraces dynamic adjustments. With real-time data analytics, warehouses can adapt slotting configurations based on evolving demand patterns, ensuring that the most frequently picked items remain easily accessible.

4. RFID Technology Integration

Radio-Frequency Identification (RFID) technology is a scientific innovation enhancing warehouse slotting. RFID tags on products provide real-time tracking, allowing for accurate inventory management and facilitating efficient slotting based on current stock levels.

5. Machine Learning Applications

Machine learning applications take warehouse slotting to a new level by predicting consumer behavior and demand patterns. These applications can analyze vast datasets to forecast trends, enabling warehouses to proactively adjust slotting configurations for optimal efficiency.

The Symbiosis of Art and Science

Successful warehouse slotting is not an either-or scenario; it’s a harmonious blend of art and science. The artistry lies in the intuitive understanding of products and consumer behavior, while the science relies on data-driven precision to optimize every inch of the warehouse.

The Evolution of Warehouse Slotting

As technology advances, so does the practice of warehouse slotting. The future promises even more sophisticated approaches to enhance efficiency. Here’s a glimpse into the evolving landscape of warehouse slotting:

1. Robotics Integration

The integration of robotics in warehouse operations is revolutionizing slotting strategies. Robots equipped with advanced sensors and algorithms can navigate through the warehouse, ensuring that products are precisely placed and easily retrievable. This not only reduces human labor but also enhances accuracy.

2. Internet of Things (IoT) Connectivity

The rise of the Internet of Things (IoT) is transforming warehouse slotting into a dynamic, interconnected system. Smart shelves and pallets equipped with IoT sensors provide real-time data on inventory levels, enabling warehouses to make instant slotting adjustments based on demand fluctuations.

3. Artificial Intelligence (AI) Enhancements

Artificial Intelligence (AI) is taking warehouse slotting to new heights. AI algorithms can analyze vast amounts of data, including historical sales, customer preferences, and market trends, to predict future demand accurately. This predictive capability allows for proactive slotting adjustments, ensuring that products are always in the optimal location.

4. Augmented Reality Applications

Augmented Reality (AR) applications are emerging as tools to guide warehouse staff during the slotting process. AR overlays real-time data onto the physical warehouse space, providing visual cues for efficient slotting decisions.

5. Predictive Analytics for Slotting Optimization

The integration of predictive analytics into ABC Analysis optimization is a future trend. By analyzing a combination of internal and external factors, warehouses can foresee changes in demand and proactively adjust slotting configurations for maximum efficiency.

Best Practices for Effective Warehouse Slotting

For organizations aiming to master the art and science of ABC Analysis, adopting best practices is essential. Here are some key recommendations:

1. Regular Slotting Audits

Regularly audit and analyze slotting configurations to ensure they align with changing market dynamics. This proactive approach prevents inefficiencies and maximizes the benefits of warehouse slotting.

2. Employee Training Programs

Equip warehouse staff with the knowledge and skills to understand the principles of effective slotting. Training programs should cover both the artistic aspects, such as product characteristics and visual merchandising, and the scientific components, including ABC analysis and algorithmic considerations.

3. Embrace Technology Upgrades

Stay at the forefront of technological advancements in warehouse management. Embrace robotics, IoT connectivity, AI enhancements, RFID technology, and AR applications to elevate the efficiency of ABC analysis practices.

4. Collaboration Across Departments

ABC Analysis is not an isolated function; it impacts various departments, including sales, marketing, and procurement. Foster collaboration across departments to gather valuable insights that can inform slotting decisions.

5. Sustainability Considerations

Incorporate sustainability considerations into slotting decisions. Efficient slotting not only reduces operational costs but also minimizes the environmental impact through optimized resource utilization and reduced energy consumption.

Conclusion

In conclusion, warehouse slotting is a multifaceted discipline that fuses art and science to optimize warehouse operations. The symbiotic relationship between intuitive practices and data-driven precision is the cornerstone of successful slotting. As technology continues to advance, embracing the evolving landscape of ABC Analysis is not just a choice but a strategic imperative for organizations aiming to thrive in the dynamic world of logistics.