Value Adding Services in Warehouse

In the fast-paced world of modern commerce, warehouses are no longer just spaces to store goods; they have evolved into dynamic hubs that play a pivotal role in the supply chain. As businesses strive to stay competitive, the integration of value adding services in warehouse operations has become a strategic imperative. In this extensive exploration, we delve into the transformative power of value addition, examining how it can revolutionize warehousing, enhance operational efficiency, and, ultimately, maximize profits.

The Essence of Value Addition

Strategic Inventory Management: Beyond Storage

At the heart of value addition lies the redefinition of the traditional role of warehouses. No longer confined to mere storage spaces, warehouses are transitioning into strategic centers for inventory management. This shift involves the implementation of intelligent systems that go beyond basic tracking. They analyze historical data, predict future demand, and optimize inventory placement, preventing overstocking or stockouts.

Customized Packaging: Beyond Protection

Packaging is not just about protecting products; it's a crucial aspect of branding and customer experience. Value adding services in warehouse include customized packaging solutions, offering tailored options that align with the brand image. From eco-friendly packaging for sustainability-conscious consumers to specialized packaging for delicate items, the goal is to make an impact from the warehouse to the customer's doorstep.

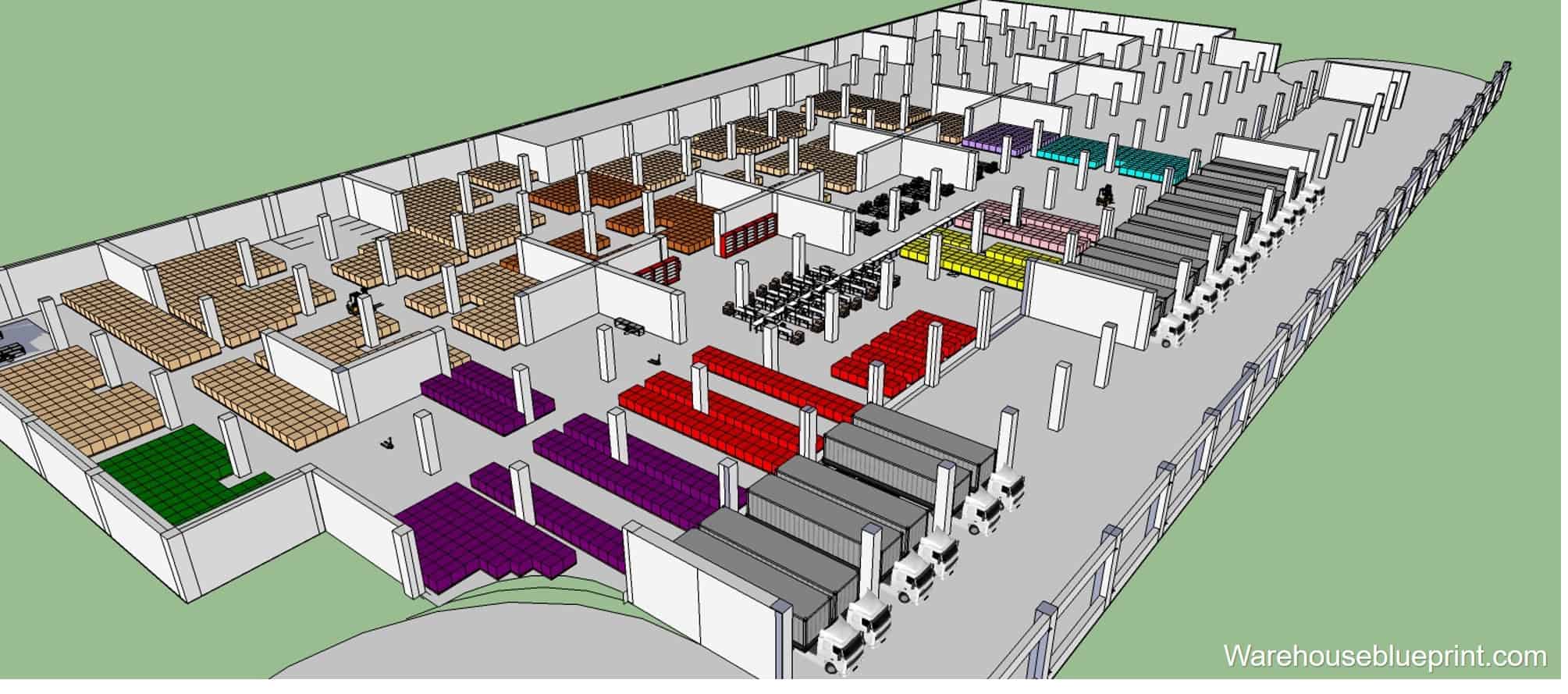

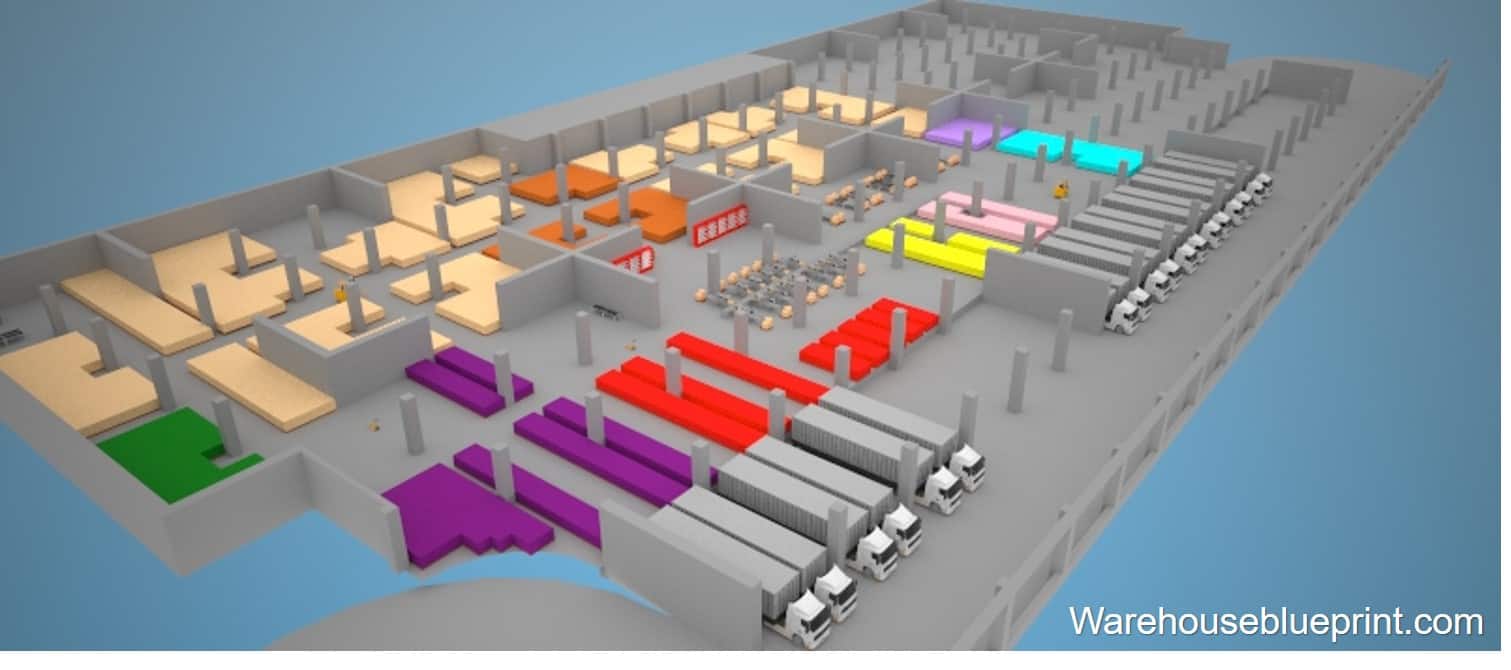

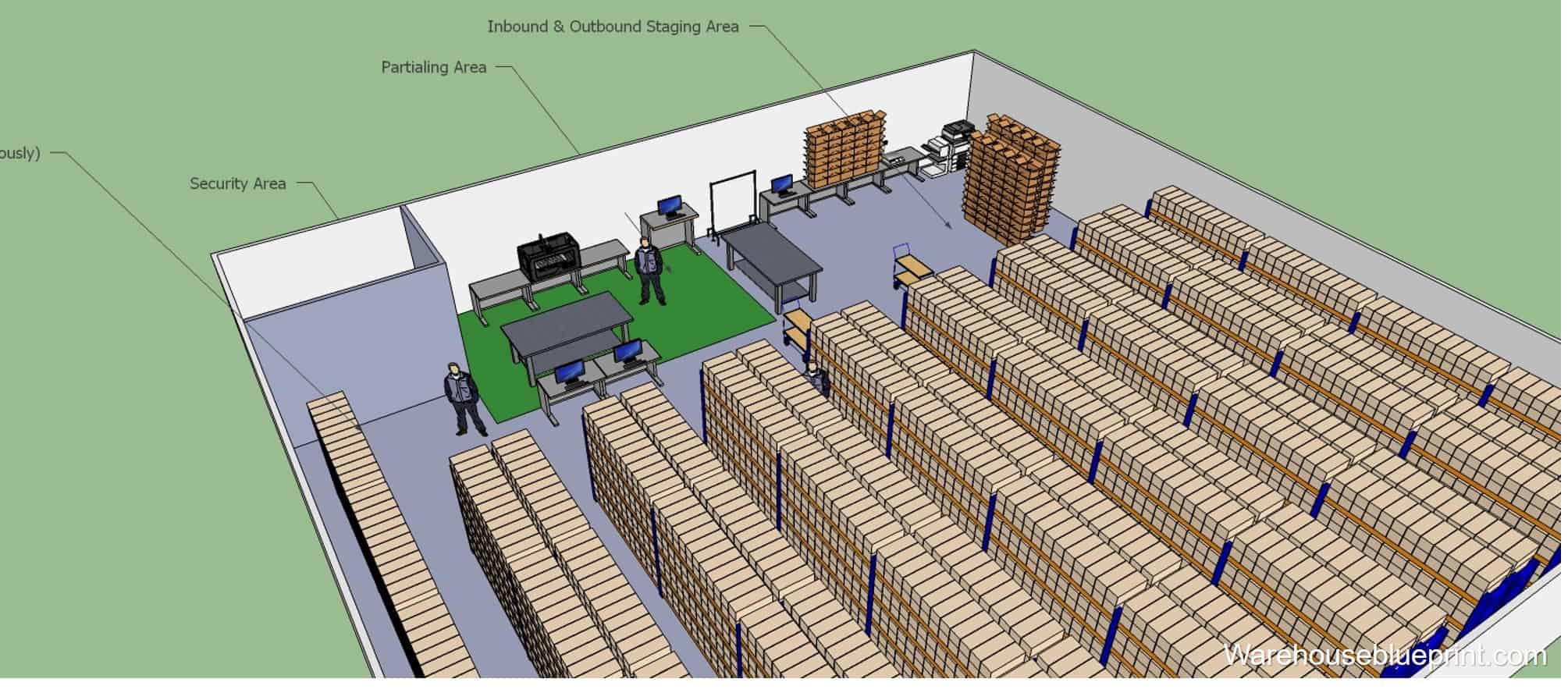

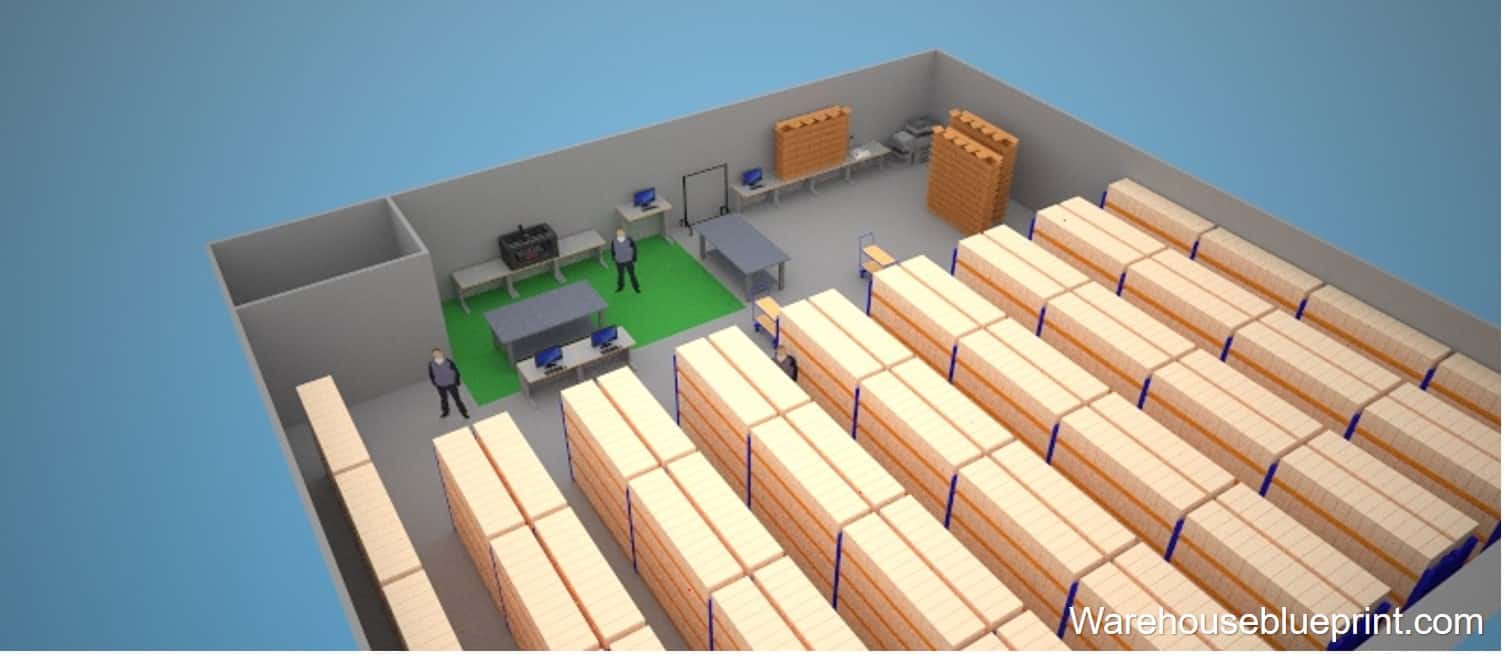

Below are some 3D images of the VAS area in 2 of the warehouses.

Warehouse A

Warehouse A shows the scanning, labelling, packing of items for dispatch. Conveyor systems, scanners, printers, workstations are setup for the VAS process.

Operational Excellence: The Engine of Efficiency

Order Fulfillment Expertise: Swift and Seamless

Efficient order fulfillment is the backbone of any successful warehouse. Beyond the conventional picking and packing processes, value adding services in warehouse focus on creating a seamless and swift order fulfillment system. This involves integrating advanced technologies, such as order batching algorithms and optimized picking routes, to ensure quicker turnaround times and heightened customer satisfaction.

Kitting and Assembly: Meeting Diverse Needs

For businesses dealing with complex products or those offering customizable bundles, value adding services in warehouse extend to kitting and assembly. Expert teams proficient in assembling, packaging, and shipping products directly from the warehouse floor reduce lead times and enhance overall efficiency. This not only caters to diverse consumer needs but also adds a layer of flexibility to warehouse operations.

Technological Innovations: Paving the Way to the Future

Automation Integration: Beyond Efficiency

The future of warehousing is intertwined with technology, and value-adding services embrace this reality. Automation integration is not just about efficiency; it's about future readiness. Warehouses equipped with robotic picking systems, automated guided vehicles (AGVs), and smart conveyor systems lay the foundation for streamlined operations and enhanced productivity.

AI-Driven Predictive Analytics: Data as a Strategic Asset

In the era of big data, value-adding services leverage AI-driven predictive analytics to transform data into a strategic asset. By analyzing trends, forecasting demand patterns, and predicting potential disruptions, warehouses equipped with this technology can proactively adapt to market dynamics. This forward-thinking approach positions businesses for sustained success in an ever-changing landscape.

Client-Centric Approach: Tailoring Services to Unique Needs

Personalized Customer Support: Going the Extra Mile

A distinguishing feature of value adding services in warehouse is a commitment to a client-centric approach. Beyond standard customer support, businesses provide dedicated account managers who deeply understand each client's unique needs. This personalized touch ensures that warehouse services align seamlessly with individual business objectives, fostering a long-term strategic partnership.

Continuous Improvement Initiatives: Adapting to Change

The dynamics of warehousing are ever-evolving, and stagnation is the enemy of progress. Value adding services in warehouse incorporate continuous improvement initiatives as a fundamental principle. Warehouses committed to ongoing optimization, cost reduction, and performance enhancement are better equipped to navigate the complexities of the market.

Conclusion: Transforming Warehousing, Transforming Business

In conclusion, the integration of value adding services in warehouse is not merely a trend; it's a paradigm shift in warehousing philosophy. Beyond the traditional role of storage, warehouses are becoming catalysts for business success. By partnering with service providers offering comprehensive value-adding solutions, businesses can unlock efficiency, maximize profits, and position themselves at the forefront of the warehousing revolution.

Check this out.

https://warehouseblueprint.com/vas

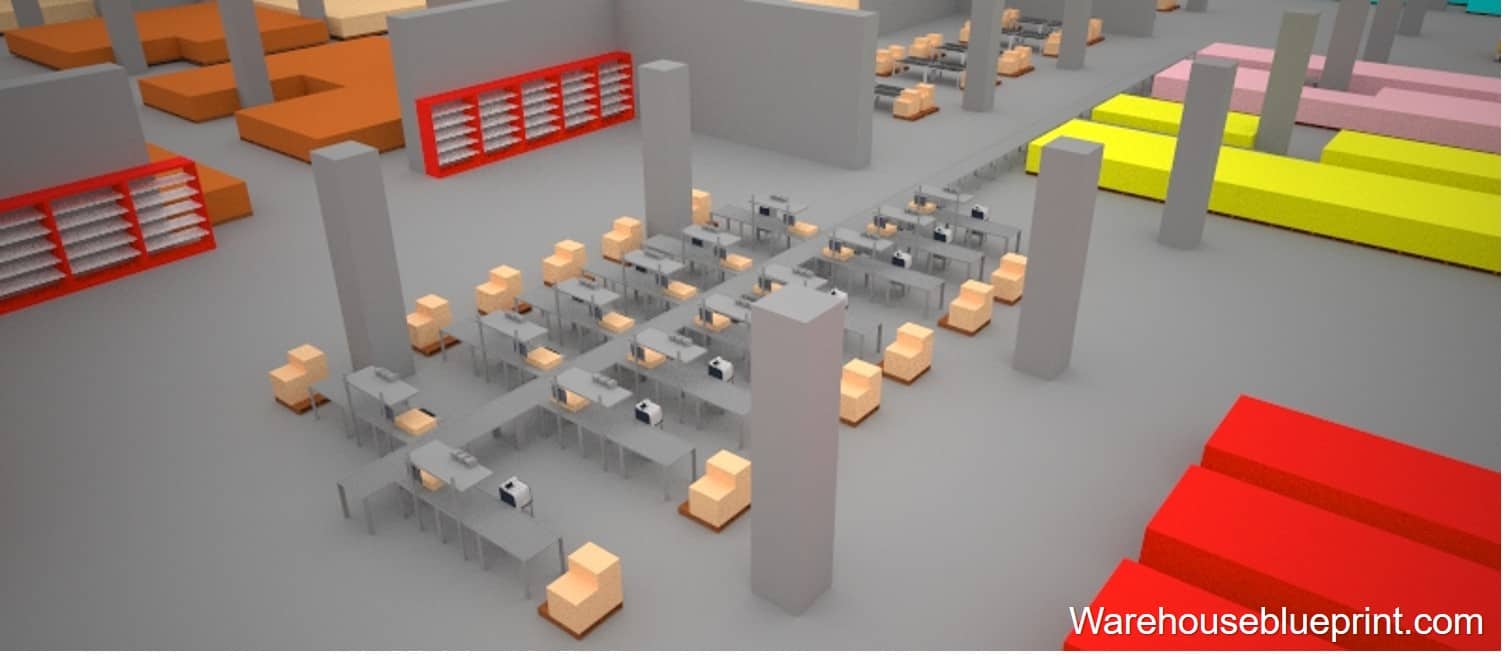

Warehouse B

Warehouse B depicts the work done to open up cartons and performing batching/ partialling of the eaches into small quantity.

For this operations, storage of the inventory are in shelving. There are no pallets stored here.

In addition, due to the high pricing of the products, tight security is an important feature here as well.