Exploring the Complexities of Inventory Oversight

In the continually evolving sphere of warehousing, the intricate orchestration of inventory management transcends mere necessity; it pulsates as the vital rhythm of operational excellence. Beyond functioning as a logistical task, proficient inventory management stands as a strategic imperative capable of reshaping the trajectory of one’s business. This extensive guide not only plunges into the depths of effective inventory oversight but also immerses itself in tangible instances, the fusion of technology, advanced warehouse arrangement, the profound significance of inventory management, and the repercussions of the ABC classification system.

Deciphering the Core of Inventory Oversight

At its essence, inventory management unfolds as a meticulous procedure encompassing the vigilant supervision and command over every aspect of a company’s stock. From the instants when goods make their entrance into the warehouse to the juncture of their departure, every movement unfolds with meticulous precision. This intricate dance guarantees optimal stock levels, curtails storage expenses, and amplifies operational efficiency.

The Crucial Function of Proficient Inventory Oversight

Strategic Imperative for Cost Efficiency

In the labyrinth of warehousing, the ceaseless quest for cost optimization persists. Proficient inventory oversight emerges as the linchpin for achieving this delicate equilibrium. It transcends the prevention of overstock or stockouts; it revolves around strategically aligning supply with demand. This strategic alignment allows businesses to diminish storage costs, minimize waste, and augment overall profitability.

Elevated Customer Contentment: Precision in Meeting Demands

In today’s consumer-centric market, meeting and surpassing customer expectations hold paramount importance. Proficient inventory oversight ensures that products are not merely present but readily accessible. Punctual deliveries become the norm, leading to heightened customer contentment. It transcends being a logistical accomplishment; it manifests as a commitment to fulfilling and exceeding customer expectations.

Operational Streamlining: Enhancing Workflow Efficiency

Envision a warehouse where items are haphazardly arranged, transforming it into a labyrinth for retrieval. Proficient inventory oversight not only maintains order but also heightens operational efficiency by diminishing picking errors, reducing travel distances, and optimizing the entire workflow. Essentially, it metamorphoses a storage space into a finely tuned machine.

Strategies for Executing Effective Inventory Oversight

Harnessing Cutting-Edge Software Solutions: Embracing Technological Progress

Investing in state-of-the-art advanced inventory management software transcends a mere modernization step; it signifies a transformative leap. These advanced tools leverage technologies such as artificial intelligence and machine learning to furnish real-time insights, accurately forecast demand, and automate routine tasks. It is not solely about managing inventory; it is about executing it with precision and intelligence.

Just-in-Time (JIT) Inventory System: The Trimmed Approach

Embracing the Just-in-Time (JIT) inventory system stands as a strategic maneuver that minimizes inventory levels by receiving goods solely as needed in the production process. This lean methodology optimizes storage space and diminishes holding costs, aligning inventory with actual demand.

Consistent Audits and Analysis: Staying Attuned to the Pulse

Consistent audits function as the lifeblood of effective inventory oversight. Regularly scrutinizing stock levels, turnover rates, and demand patterns enables businesses to adapt promptly to market fluctuations. It involves staying proactive and responsive in a dynamic market environment.

Warehouse Arrangement: Fine-Tuning the Spatial Harmony

Warehouse slotting emerges as an art form that optimizes the spatial configuration of products within a warehouse. It entails strategically positioning items based on their demand frequency, size, and picking patterns. High-demand items find their place closer to shipping areas, reducing travel time, and enhancing overall efficiency. This methodical organization is not merely about storage; it orchestrates a symphony of efficiency within the warehouse.

Navigating Obstacles in Inventory Oversight

Disruptions in the Supply Chain

Global events, geopolitical shifts, or unforeseen circumstances can disrupt the seamless flow of the supply chain. A resilient inventory management system mitigates these challenges by offering flexibility and adaptability.

Challenges in Technology Integration

While technology proves advantageous, integrating new systems into existing operations can be formidable. Surmounting these hurdles is crucial to harness the full potential of advanced inventory management solutions.

Glimpsing into the Future: Evolution of Inventory Oversight

As we stand at the threshold of a new era, the future of inventory oversight is poised for groundbreaking innovations. From the integration of Internet of Things (IoT) devices for real-time tracking to the implementation of blockchain for enhanced transparency, the landscape is evolving, promising even greater efficiency.

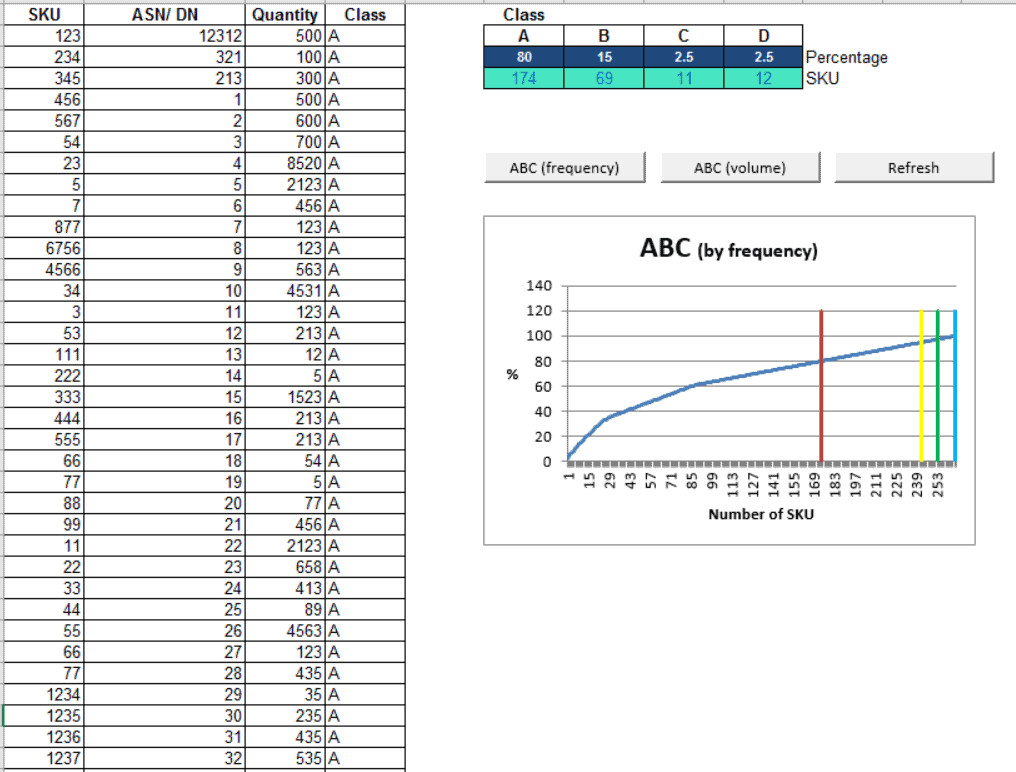

The ABC Classification System: Unveiling Inventory Prioritization

Strategic Allocation of Resources: Maximizing Effectiveness

The ABC classification system empowers businesses to allocate resources strategically. By recognizing the varying importance of items, businesses can channel their focus, time, and resources more efficiently.

Optimized Replenishment Strategies: Balancing Demand and Cost

Grasping the ABC classification aids in tailoring replenishment strategies. For A-Class items, where stockouts can be costly, businesses may opt for more conservative inventory levels and implement just-in-time replenishment strategies.

Risk Mitigation: Proactive Decision-Making

The ABC classification system facilitates risk mitigation by enabling businesses to identify and prioritize items with the highest impact on revenue.

Dynamic Forecasting: Adapting to Market Changes

The dynamic nature of the ABC classification system aligns well with the unpredictable nature of markets. A-Class items may require more frequent and sophisticated forecasting techniques to adapt promptly to market changes.

Optimizing Warehouse Slotting: Streamlining Operations

The ABC classification system extends its influence to warehouse slotting. By categorizing items based on their importance, businesses can optimize the physical layout of their warehouses.

In Conclusion

Understanding the intricate ballet of inventory oversight in warehousing is not merely a managerial task; it stands as a strategic imperative. Businesses mastering the art of proficient inventory oversight position themselves as leaders in the competitive marketplace, ensuring not only sustainability but robust growth. The integration of advanced technology, coupled with strategic categorization systems like ABC, propels businesses into a future where efficiency, precision, and adaptability take center stage.